Turbine Flow Rate Sensor

Turbine Flow Rate Sensor - Web asme does not “approve,” “rate,” or “endorse” any item, construction, proprietary device, or activity. Asme does not take any position with respect to the validity of any patent rights asserted in connection with any The sensors are based on optical fiber sensing technologies following two major principles: Lower flow ranges from 0.1 to 8 gpm (0.5 to 30 l/min) compact and lightweight footprint. Web turbine flow meters measure the rate of flow in a pipe or process line via a rotor that spins as the media passes through its blades. Turbine flow meter is the most popular equipment to measure the velocity of liquids and gases.

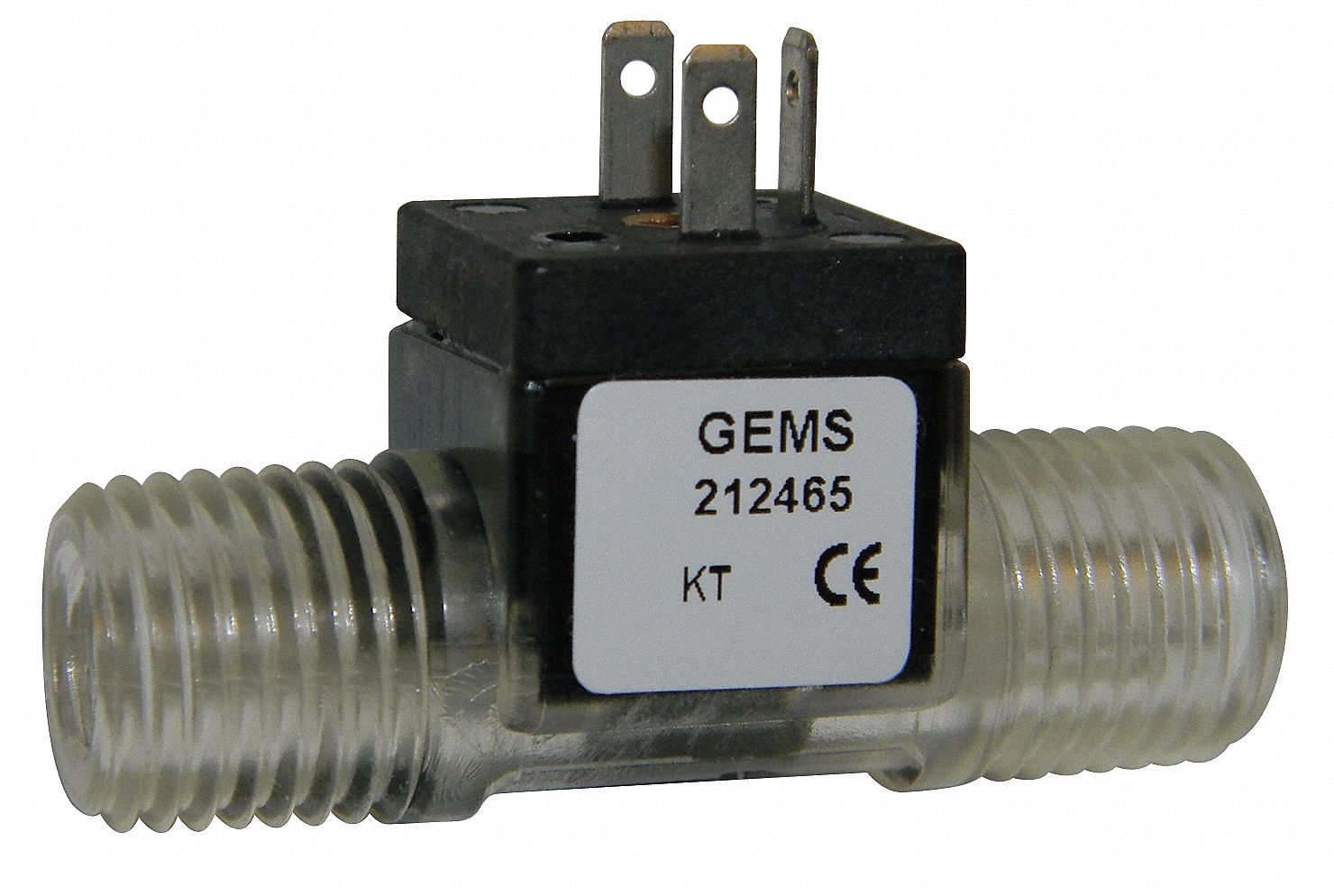

Fiber bragg gratings (fbgs) and intensity. Gems hall effect turbine flow rate sensor is ideal for oem applications involving low flow liquid monitoring. Web we find that with opportune siting, kinetic energy can be extracted efficiently without compromising the geomorphic equilibrium of the river and the structural safety of the turbine foundation,. Offered in a choice of high strength anodized aluminum or stressproof® steel bodies, these durable flow sensors are capable of withstanding pressures up to 6000 psi (414 bar). Turbine flow meters are used in a wide variety of liquid and gas flow sensing applications.

Web what are turbine flow meters? Web flr1000 series flow sensors can measure extremely low flow rates from 20 ml/min to 500 l/min. Turbine flow meters are used in a wide variety of liquid and gas flow sensing applications. Web this paper presents the development of a smart structure comprised of a hydraulic metering arrangement for simultaneous data readings of temperature, flow rate, salinity, ph and turbidity in liquids. Web turbine flow meters measure the rate of flow in a pipe or process line via a rotor that spins as the media passes through its blades.

Available in nylon 12 or brass housings with nsf certified option available. In most turbine flow meters, magnets are fitted to the blades, and a magnetic pickup sensor is used to create the pulses. Web turbine flowmeters are engineered to accurately measure the flow of liquids and gases in pipes. The flowing fluid engages the rotor causing it to rotate.

Web turbine flow meters for fuel. These sensors are suitable for a wide variety of industrial, commercial, and laboratory flow applications. The flowing fluid engages the rotor causing it to rotate at an angular velocity proportional to the fluid flow rate. Lower flow ranges from 0.1 to 8 gpm (0.5 to 30 l/min) compact and lightweight footprint. The low cost.

They measure flow on a volumetric basis. Web if you need volumetric total flow and/or flow rate measurement, a turbine flow meter is the ideal device. This deep dive aims to provide you with a clear understanding of how these devices can fit into and benefit your operational needs. Web this paper presents the development of a smart structure comprised.

Web in this comprehensive guide, we will delve into the world of turbine flow meters, exploring their working principle, advantages, drawbacks, and applications. Lower flow ranges from 0.1 to 8 gpm (0.5 to 30 l/min) compact and lightweight footprint. Web if you need volumetric total flow and/or flow rate measurement, a turbine flow meter is the ideal device. Web sika’s.

The higher the rate of flow, the faster the rotor turns and the greater the number of pulses. These sensors are suitable for a wide variety of industrial, commercial, and laboratory flow applications. The flow rate of hydraulic fluids and other compatible liquids. Web turbine flow sensors provide low flow rates and high accuracy for low flow liquid monitoring. Web.

The sensors are based on optical fiber sensing technologies following two major principles: Web what are turbine flow meters? Web turbine flow sensors provide low flow rates and high accuracy for low flow liquid monitoring. Web sika’s vtr turbine flow sensor allows you to determine precisely, dependably and easily the flow rates of different liquids, such as water and other.

The classic series with the standard magnetic Offered in a choice of high strength anodized aluminum or stressproof® steel bodies, these durable flow sensors are capable of withstanding pressures up to 6000 psi (414 bar). These meters operate on the principle of fluid flowing through a turbine rotor, causing it to rotate. The different flow fields downstream of. Asme does.

Web if you need volumetric total flow and/or flow rate measurement, a turbine flow meter is the ideal device. Web turbine flowmeters are engineered to accurately measure the flow of liquids and gases in pipes. These meters operate on the principle of fluid flowing through a turbine rotor, causing it to rotate. Web flr1000 series flow sensors can measure extremely.

Web turbine flowmeters are engineered to accurately measure the flow of liquids and gases in pipes. Offered in a choice of high strength anodized aluminum or stressproof® steel bodies, these durable flow sensors are capable of withstanding pressures up to 6000 psi (414 bar). Web unstable flows in the runner of water turbines, such as reverse flow, vorticity and flow.

Web if you need volumetric total flow and/or flow rate measurement, a turbine flow meter is the ideal device. Lower flow ranges from 0.1 to 8 gpm (0.5 to 30 l/min) compact and lightweight footprint. They measure flow on a volumetric basis. Asme does not take any position with respect to the validity of any patent rights asserted in connection.

Turbine Flow Rate Sensor - Web unstable flows in the runner of water turbines, such as reverse flow, vorticity and flow direction transition, are the main factors causing increased losses and decreased efficiency, and changing the geometry structure in the downstream of the runner is an important means of mitigating these instabilities. The flow rate of hydraulic fluids and other compatible liquids. Web we find that with opportune siting, kinetic energy can be extracted efficiently without compromising the geomorphic equilibrium of the river and the structural safety of the turbine foundation,. Web turbine flowmeters are engineered to accurately measure the flow of liquids and gases in pipes. The classic series with the standard magnetic Fiber bragg gratings (fbgs) and intensity. Web sika’s vtr turbine flow sensor allows you to determine precisely, dependably and easily the flow rates of different liquids, such as water and other low viscosity liquids, under the most severe conditions. In most turbine flow meters, magnets are fitted to the blades, and a magnetic pickup sensor is used to create the pulses. Lower flow ranges from 0.1 to 8 gpm (0.5 to 30 l/min) compact and lightweight footprint. Asme does not take any position with respect to the validity of any patent rights asserted in connection with any

Crafted with meticulous attention to accuracy and reliability, this sensor utilizes hall effect technology to deliver unparalleled performance. These sensors are suitable for a wide variety of industrial, commercial, and laboratory flow applications. Turbine flow meter is the most popular equipment to measure the velocity of liquids and gases. The low cost coupled with 1/2% repeatability makes it an. Web if you need volumetric total flow and/or flow rate measurement, a turbine flow meter is the ideal device.

The low cost coupled with 1/2% repeatability makes it an. Web what are turbine flow meters? They measure flow on a volumetric basis. These meters operate on the principle of fluid flowing through a turbine rotor, causing it to rotate.

Offered in a choice of high strength anodized aluminum or stressproof® steel bodies, these durable flow sensors are capable of withstanding pressures up to 6000 psi (414 bar). Lower flow ranges from 0.1 to 8 gpm (0.5 to 30 l/min) compact and lightweight footprint. The higher the rate of flow, the faster the rotor turns and the greater the number of pulses.

Available in nylon 12 or brass housings with nsf certified option available. Gems hall effect turbine flow rate sensor is ideal for oem applications involving low flow liquid monitoring. Web flr1000 series flow sensors can measure extremely low flow rates from 20 ml/min to 500 l/min.

Available In Nylon 12 Or Brass Housings With Nsf Certified Option Available.

Web flr1000 series flow sensors can measure extremely low flow rates from 20 ml/min to 500 l/min. Web in this comprehensive guide, we will delve into the world of turbine flow meters, exploring their working principle, advantages, drawbacks, and applications. The different flow fields downstream of. Web turbine flow meters measure the rate of flow in a pipe or process line via a rotor that spins as the media passes through its blades.

The Classic Series With The Standard Magnetic

The low cost coupled with 1/2% repeatability makes it an. Web unstable flows in the runner of water turbines, such as reverse flow, vorticity and flow direction transition, are the main factors causing increased losses and decreased efficiency, and changing the geometry structure in the downstream of the runner is an important means of mitigating these instabilities. Prior to installation, confirm system versus sensor specifications and media compatibility of sensor. These sensors are suitable for a wide variety of industrial, commercial, and laboratory flow applications.

Lower Flow Ranges From 0.1 To 8 Gpm (0.5 To 30 L/Min) Compact And Lightweight Footprint.

Web this paper presents the development of a smart structure comprised of a hydraulic metering arrangement for simultaneous data readings of temperature, flow rate, salinity, ph and turbidity in liquids. The flowing fluid engages the rotor causing it to rotate at an angular velocity proportional to the fluid flow rate. Web if you need volumetric total flow and/or flow rate measurement, a turbine flow meter is the ideal device. Offered in a choice of high strength anodized aluminum or stressproof® steel bodies, these durable flow sensors are capable of withstanding pressures up to 6000 psi (414 bar).

Asme Does Not Take Any Position With Respect To The Validity Of Any Patent Rights Asserted In Connection With Any

Web turbine flow sensors provide low flow rates and high accuracy for low flow liquid monitoring. Web turbine flow meters for fuel. The flow rate of hydraulic fluids and other compatible liquids. Turbine flow meter is the most popular equipment to measure the velocity of liquids and gases.