Mig Welding Weave Patterns

Mig Welding Weave Patterns - There are different mig welding patterns, such as the stringer bead pattern, weave pattern, and whip pattern, each serving a specific purpose and offering unique advantages. Just as a note in most shipyards weaving is not allowed. The stringer weld pattern is the simplest and most basic weld pattern for mig welding. Stringer beads weave beads however, once you decide to create weld beads, there are different variations of the weave pattern which look different and differ from the straight weld. Web the two main types of welding bead patterns are stringers and weaves. This technique produces a deep weld penetration and higher overall quality.

Web the correct choice of welding pattern can significantly impact the overall strength and durability of the weld. When & how to use them. Web weaving welding technique pattern. It's used when you make two or more welds on the same seam. Web weave bead welding involves making a weaving pattern in order to cover a larger surface area.

Web by using different weave patterns, welders can control the amount of heat and penetration, ensuring the weld is strong and secure. You use this motion to make cover welds over stringer beads (multipass welding). Common mig welding patterns and techniques: Web what are weave patterns in mig welding? Web save 8.3k views 4 years ago elite partner matti christensen has mastered the weave technique with mig welding.

Stringer beads weave beads however, once you decide to create weld beads, there are different variations of the weave pattern which look different and differ from the straight weld. For thin materials, a narrow weave pattern is typically preferred. This technique involves moving the torch or gun in a circular pattern along the joint. Weaves are used for wider welds.

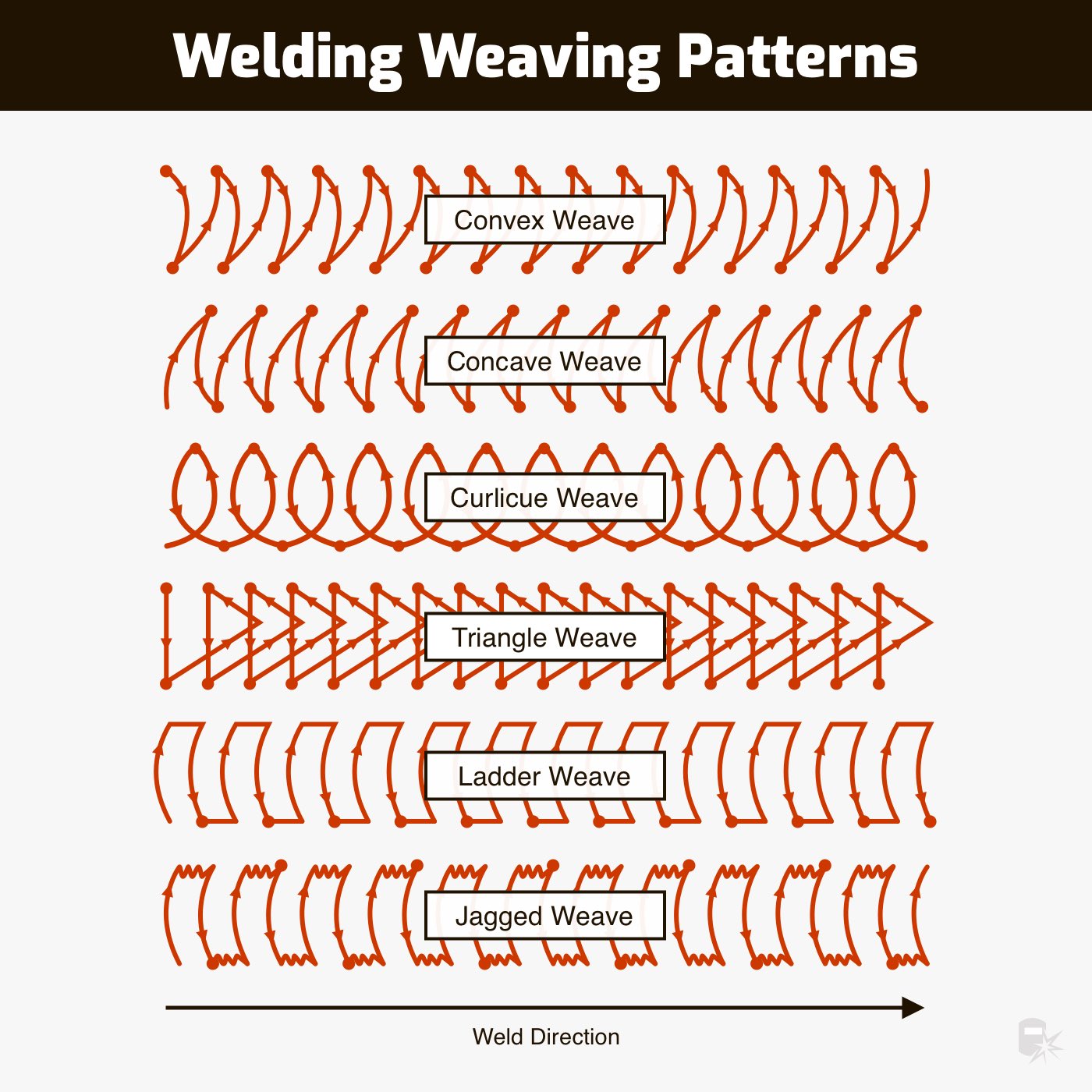

Here are the seven essential mig welding patterns that will lead you to become an experienced welder. Depending on the material being welded, its thickness, and. Rotate pipe towards you while. You will make a weaving pattern in order to cover a larger area. There are many things to remember when setting up your mig welding machine.

Properly executed weave patterns ensure uniform heat distribution, prevent overheating. Welding bead types tig welding beads Web what are weave patterns in mig welding? Web choosing the right mig welding pattern welding thin materials:. Weave bead welding is exactly as it sounds;

Stringer beads weave beads however, once you decide to create weld beads, there are different variations of the weave pattern which look different and differ from the straight weld. Web 6 essential mig welding patterns to master 1. Easy shipping & deliverywide variety of stylestop brand tools Learning different bead types will help you figure out what is beneficial for.

In other words you use this when you are layering welds. Web generally speaking, there are two main welding bead techniques and patterns: Web the correct choice of welding pattern can significantly impact the overall strength and durability of the weld. Stringer beads weave beads however, once you decide to create weld beads, there are different variations of the weave.

Web alternative patterns for mig welding holding still. This results in a broader, more substantial bead and is particularly beneficial for filling large gaps or when working with thicker materials. The circle weld pattern is a more advanced weld pattern that involves moving the welding. Learning different bead types will help you figure out what is beneficial for your specific.

Easy shipping & deliverywide variety of stylestop brand tools The stringer weld pattern is the simplest and most basic weld pattern for mig welding. Depending on the material being welded, its thickness, and. In other words you use this when you are layering welds. We like to think of using “welding patterns” to achieve different bead profiles.

For thin materials, a narrow weave pattern is typically preferred. Metal inert gas (mig) welding: The stringer weld pattern is the simplest and most basic weld pattern for mig welding. These patterns significantly impact the final weld bead's shape, size, and penetration depth. The most common sticking welding pattern is the weave.

Web some common weave patterns include: For thin materials, a narrow weave pattern is typically preferred. Web the four easiest mig welding patterns for beginners to learn and master are the steady motion pattern, the whipping pattern, the circle pattern, and the weave pattern. Learning different bead types will help you figure out what is beneficial for your specific projects.

We like to think of using “welding patterns” to achieve different bead profiles. Properly executed weave patterns ensure uniform heat distribution, prevent overheating. Weaves are good for big joints that have no distortion issues. Web 6 essential mig welding patterns to master 1. This is the most basic and straightforward pattern, involving a simple linear motion.

Mig Welding Weave Patterns - Weave bead welding is exactly as it sounds; Web alternative patterns for mig welding holding still. In other words you use this when you are layering welds. Properly executed weave patterns ensure uniform heat distribution, prevent overheating. It's used when you make two or more welds on the same seam. Web the correct choice of welding pattern can significantly impact the overall strength and durability of the weld. Depending on the material being welded, its thickness, and. There are different mig welding patterns, such as the stringer bead pattern, weave pattern, and whip pattern, each serving a specific purpose and offering unique advantages. While simple, mastering the speed and movement consistency is vital for achieving a good weld. Web weaving welding technique pattern.

Properly executed weave patterns ensure uniform heat distribution, prevent overheating. The stringer weld pattern is the simplest and most basic weld pattern for mig welding. Web the correct choice of welding pattern can significantly impact the overall strength and durability of the weld. Easy shipping & deliverywide variety of stylestop brand tools Here are the seven essential mig welding patterns that will lead you to become an experienced welder.

There are many things to remember when setting up your mig welding machine. Web this article will cover the types of welding beads that are common with the three main processes ( tig, stick, mig ). Properly executed weave patterns ensure uniform heat distribution, prevent overheating. Welding bead types tig welding beads

Just as a note in most shipyards weaving is not allowed. In other words you use this when you are layering welds. Web 6 essential mig welding patterns to master 1.

This results in a broader, more substantial bead and is particularly beneficial for filling large gaps or when working with thicker materials. Web the two main types of welding bead patterns are stringers and weaves. As the name implies, you set up the mig welder in the place it needs to be and then hold it steady.

We Like To Think Of Using “Welding Patterns” To Achieve Different Bead Profiles.

Weaves are used for wider welds and range from a tight side to side motion that can be a stringer bead to welds that are wide and big for a single pass. Web choosing the right mig welding pattern welding thin materials:. This motion allows you to make cover welds over stringer beads, otherwise known as multipass welding. While simple, mastering the speed and movement consistency is vital for achieving a good weld.

When & How To Use Them.

It's used when you make two or more welds on the same seam. Web weaving welding technique pattern. Welding bead types tig welding beads Here are the seven essential mig welding patterns that will lead you to become an experienced welder.

These Patterns Significantly Impact The Final Weld Bead's Shape, Size, And Penetration Depth.

This technique produces a deep weld penetration and higher overall quality. When welding thick materials, a stringer pattern is often the best choice. Web what are weave patterns in mig welding? You use this motion to make cover welds over stringer beads (multipass welding).

Web 6 Essential Mig Welding Patterns To Master 1.

The weaving welding technique involves making a series of overlapping circles with the electrode as you progress along the stable full arc length of the weld joint. This is the most basic and straightforward pattern, involving a simple linear motion. In other words you use this when you are layering welds. Stringer beads weave beads however, once you decide to create weld beads, there are different variations of the weave pattern which look different and differ from the straight weld.