Hall Effect Sensor Bldc

Hall Effect Sensor Bldc - Web hall effect sensor is a small transducer that plays a crucial role in a bldc motor controller. Web therefore, bldc motors always incorporate the external position sensors known as hall sensors, to sense the actual rotor position, or the position can be detected without sensors using bemf zero cross detection method. The incremental sensors, the three hall effect sensor, and the resolver. Web in this system, the trapezoidal control of bldc motors using hall effect sensors will be experimented and will explore the performance of the speed controller. Web the bldc hall sensors are now configured as a three channel, low resolution, encoder capable of delivering accurate data to aid in navigation and wheel position sensing without hindering their primary motor control function. If the sensors are not spaced accurately, the controller will have a hard time and the motor may not run smooth.

To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors. Web bldc motor needs electronic commutation, in which based on rotor position drive circuit energize stator winding. Web you can place the sensors in the gaps between teeth. If the sensors are not spaced accurately, the controller will have a hard time and the motor may not run smooth. Thus bldc demands position sensing.

Bldc is almost the same as pm dc motor with a difference that instead of commutating rotor with brush commutator, the commutation is done on stator windings by use of electronic switches. This topic shows how to drive a sensored bldc motor using an arduino uno board. Web in this system, the trapezoidal control of bldc motors using hall effect sensors will be experimented and will explore the performance of the speed controller. Software up to this point is also simple. This blog highlights, how a hall effect sensor works in a motor control system and underlines its advantages.

Web hall sensors are used for correct six step commutation used in bldc control. Web hall effect sensor is a small transducer that plays a crucial role in a bldc motor controller. Three common types of position sensors are used: Figure 2 shows a simplified representation of a single pole pair bldc motor with hall sensors (h0, h1, h2). This.

Web velocity feedback can be derived from the position data, eliminating a separate velocity transducer for the speed control loop. Web the easiest method of detecting the rotor position is hall effect sensor. Web with hall effect sensors, a simple bldc control system needs only 9 pins from a microcontroller; Web you can place the sensors in the gaps between.

To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors. Web in this system, the trapezoidal control of bldc motors using hall effect sensors will be experimented and will explore the performance of the speed controller..

Web bldc motor needs electronic commutation, in which based on rotor position drive circuit energize stator winding. Web a digital hall effect sensor (also called buffered hall effect sensor) detects the strength of the currently present magnetic field, and has a single output wire with two possible output states: Web sensored bldc motor uses hall effect sensors to detect rotor.

Web the bldc hall sensors are now configured as a three channel, low resolution, encoder capable of delivering accurate data to aid in navigation and wheel position sensing without hindering their primary motor control function. Web with hall effect sensors, a simple bldc control system needs only 9 pins from a microcontroller; Web bldc motor needs electronic commutation, in which.

Figure 2 shows a simplified representation of a single pole pair bldc motor with hall sensors (h0, h1, h2). Carolus andrews, manny soltero, mekre mesganaw. Web the easiest method of detecting the rotor position is hall effect sensor. Bldc is almost the same as pm dc motor with a difference that instead of commutating rotor with brush commutator, the commutation.

Web therefore, bldc motors always incorporate the external position sensors known as hall sensors, to sense the actual rotor position, or the position can be detected without sensors using bemf zero cross detection method. Carolus andrews, manny soltero, mekre mesganaw. Three common types of position sensors are used: To actualize motion in a system, various motor types can be used,.

Web with hall effect sensors, a simple bldc control system needs only 9 pins from a microcontroller; Web therefore, bldc motors always incorporate the external position sensors known as hall sensors, to sense the actual rotor position, or the position can be detected without sensors using bemf zero cross detection method. Rotor position can be known by using various sensors.

Web velocity feedback can be derived from the position data, eliminating a separate velocity transducer for the speed control loop. Web hall sensors are used for correct six step commutation used in bldc control. If the sensors are not spaced accurately, the controller will have a hard time and the motor may not run smooth. Web therefore, bldc motors always.

Try to center the sensors in the gaps. Three common types of position sensors are used: Rotor position can be known by using various sensors like hall sensor. Web a digital hall effect sensor (also called buffered hall effect sensor) detects the strength of the currently present magnetic field, and has a single output wire with two possible output states:.

Hall Effect Sensor Bldc - Three common types of position sensors are used: If the sensors are not spaced accurately, the controller will have a hard time and the motor may not run smooth. Web bldc motor needs electronic commutation, in which based on rotor position drive circuit energize stator winding. Bldc is almost the same as pm dc motor with a difference that instead of commutating rotor with brush commutator, the commutation is done on stator windings by use of electronic switches. Figure 2 shows a simplified representation of a single pole pair bldc motor with hall sensors (h0, h1, h2). Web sensored bldc motor uses hall effect sensors to detect rotor position where as the sensorless bldc motor uses another technique which is bemf (back electromotive force). Web a digital hall effect sensor (also called buffered hall effect sensor) detects the strength of the currently present magnetic field, and has a single output wire with two possible output states: To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors. Carolus andrews, manny soltero, mekre mesganaw. Web with hall effect sensors, a simple bldc control system needs only 9 pins from a microcontroller;

Web therefore, bldc motors always incorporate the external position sensors known as hall sensors, to sense the actual rotor position, or the position can be detected without sensors using bemf zero cross detection method. To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors. Web a digital hall effect sensor (also called buffered hall effect sensor) detects the strength of the currently present magnetic field, and has a single output wire with two possible output states: Web you can place the sensors in the gaps between teeth. Bldc is almost the same as pm dc motor with a difference that instead of commutating rotor with brush commutator, the commutation is done on stator windings by use of electronic switches.

Web you can place the sensors in the gaps between teeth. To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors. Web in this system, the trapezoidal control of bldc motors using hall effect sensors will be experimented and will explore the performance of the speed controller. If the sensors are not spaced accurately, the controller will have a hard time and the motor may not run smooth.

Web with hall effect sensors, a simple bldc control system needs only 9 pins from a microcontroller; Hall effect sensors are embedded on motor stator works on hall effect; The incremental sensors, the three hall effect sensor, and the resolver.

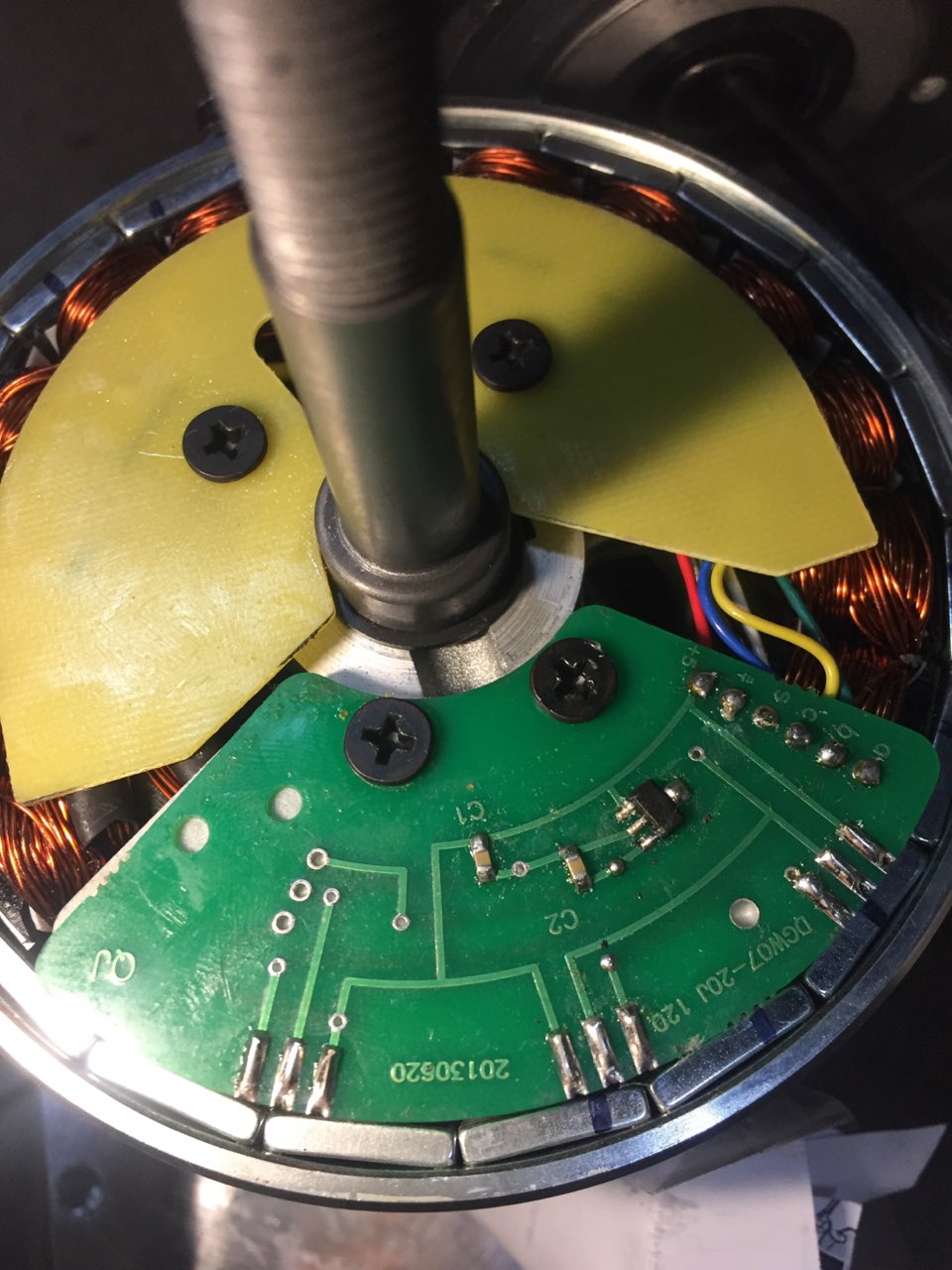

According to the standard configuration, a brushless dc (bldc) consists of three hall sensors located electrically 120 degrees apart. Web with hall effect sensors, a simple bldc control system needs only 9 pins from a microcontroller; The incremental sensors, the three hall effect sensor, and the resolver.

The Slg46620 Also Contains Other Features That Can Be Used For This Project.

Web hall effect sensor is a small transducer that plays a crucial role in a bldc motor controller. Software up to this point is also simple. Web a digital hall effect sensor (also called buffered hall effect sensor) detects the strength of the currently present magnetic field, and has a single output wire with two possible output states: Web therefore, bldc motors always incorporate the external position sensors known as hall sensors, to sense the actual rotor position, or the position can be detected without sensors using bemf zero cross detection method.

This Topic Shows How To Drive A Sensored Bldc Motor Using An Arduino Uno Board.

Web you can place the sensors in the gaps between teeth. Web velocity feedback can be derived from the position data, eliminating a separate velocity transducer for the speed control loop. Web bldc motor needs electronic commutation, in which based on rotor position drive circuit energize stator winding. Web a hall effect sensor varies its output voltage based on the strength of the applied magnetic field.

The Incremental Sensors, The Three Hall Effect Sensor, And The Resolver.

Carolus andrews, manny soltero, mekre mesganaw. If the sensors are not spaced accurately, the controller will have a hard time and the motor may not run smooth. Web in this system, the trapezoidal control of bldc motors using hall effect sensors will be experimented and will explore the performance of the speed controller. To actualize motion in a system, various motor types can be used, such as brushed direct current (dc) motors, brushless dc motors (bldc), alternating current (ac) motors, universal motors, stepper motors, or servo motors.

Three Common Types Of Position Sensors Are Used:

Try to center the sensors in the gaps. Bldc is almost the same as pm dc motor with a difference that instead of commutating rotor with brush commutator, the commutation is done on stator windings by use of electronic switches. Web sensored bldc motor uses hall effect sensors to detect rotor position where as the sensorless bldc motor uses another technique which is bemf (back electromotive force). Figure 2 shows a simplified representation of a single pole pair bldc motor with hall sensors (h0, h1, h2).